- ashirwadmachtech@gmail.com

- +91 7878451230

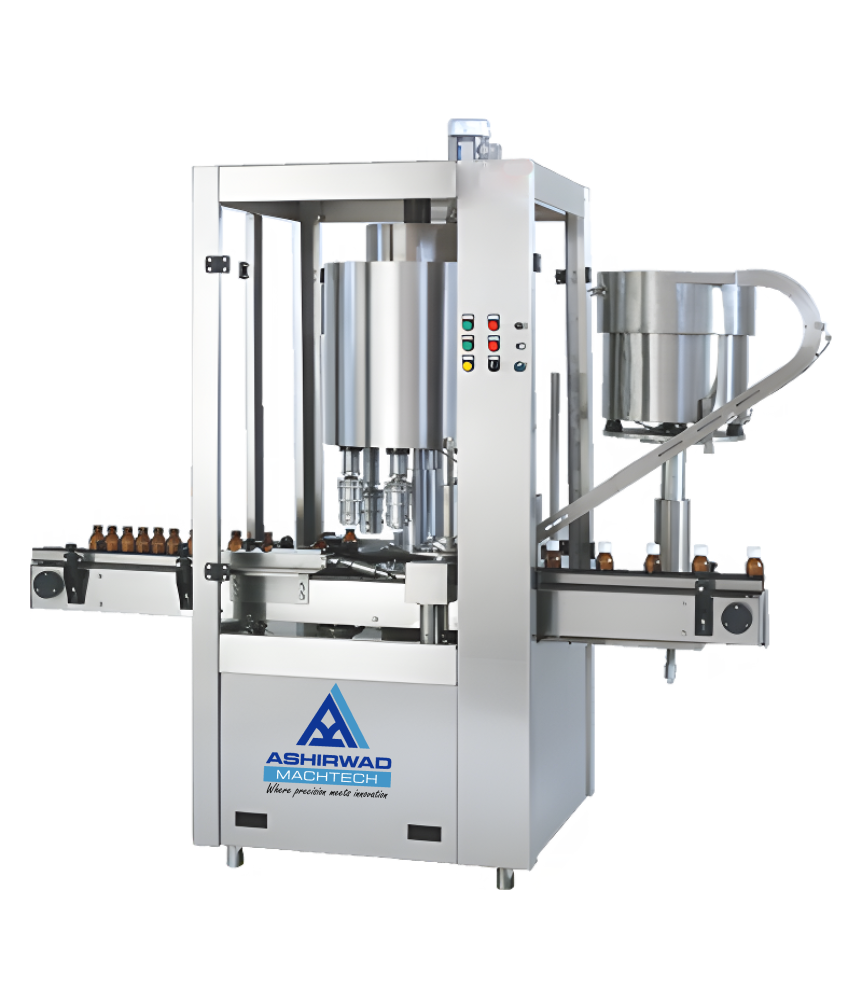

Automatic eight-head-pick-place-screw-capping machine

Automatic Screw Capping Machine is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine.

The feed container moving on conveyor belt are feed into an in-feed star wheel, bringing the container below the capping head in the subsequent indexing part, mean while the rotating head pickup a cap from the cap star wheel which is receiving from delivery chute of cap filling bowl, where the body and the neck of the container are positioned below the rotating head, where the capping head is performing perfect operation of capping, rotating head is design to seal container according to pre-set torque.

Capping machine for Pharmaceutical, Agro, Food & Beverage, Dairy, Oil Industry, Hair oil, Edible / Mustard, / Lube& Cooking, Healthcare, Toiletry and Cosmetics, Personal Care, Logistics, E-Liquid/Vaping, Medical Device and many more, Vial Capper machine, Round Bottle capper machine, Jar capper machine, Cans cap sealing machine, Square Bottle screw capping machine with systems, Jar Capping machine, Cans cap sealing machine, Flat Bottle cap sealing machine, Bucket Lid pressing machine, Container Capper machine, Capping machine with Cap Feeding bowl, Elevator, Rotary feeder with bulk cap feeding.

Salient Features

- 7”color touch screen with plc for various error message and control system

- Fast product change overs

- Integrated fault light and alarm to inform operator production error

- Accurate and repeatable performance

- All contact parts are SS 304,Delrin, Aluminum, Silicon, MS frame structure with SS cladding

- No bottle no capping system

- Motorized height adjustment of capping heads

- Cap Feeder Auto On/Off system

- Machine auto on / off system, it will start automatically once bottle enter to the in feed conveyor and stop if bottle absence

- Fully interlocked guarding for protection safety

- Synchronized variable speed control

Technical specifications

| Model | ARCS-60 | ARCS-100 | ARCS-150 | ARCS-200 |

| Output/Hour | 2400 to 3600 | 3600 to 6000 | 3600 to 9000 | 4000 to 1200 |

| Direction of Movement | Left to right | Left to right | Left to right | Left to right |

| No. of Head | 1 Nos | 4 Nos | 6 Nos | 8 Nos |

| Main Motor | 1 HP | 1.5 HP | 1.5 HP | 2 HP |

| Cap feeding bowl | 0.25 HP/415 Volts/50Hz | |||

| Height of conveyor | 860 mm to 910 mm adjustable | |||

| Overall Dimension | 2200mm(L)X1250mm(W)x2000mm(H) Approx. | |||

Countries We Export

The products are also exported to various African, United States, Gulf, Middle East & European etc. countries both directly.

| United States | United States |

| Gulf | Bahrain, Kuwait, Iraq, Oman, Qatar, Saudi Arabia and the United Arab Emirates. |

| European | Belgium, Bulgaria, Czechia, Denmark, France, Germany, Greece, Italy, Luxembourg, Malta, Netherlands 9 Russia, Ukraine, Spain, Sweden, Norway, Finland, Poland, United Kingdom. |

| African |

|

| Middle East | Lebanon, Syria, Israel, Jordan, Saudi Arabia, Yemen, Oman, Bahrain, Qatar, United Arab Emirates, Kuwait, Iraq, and Iran. |